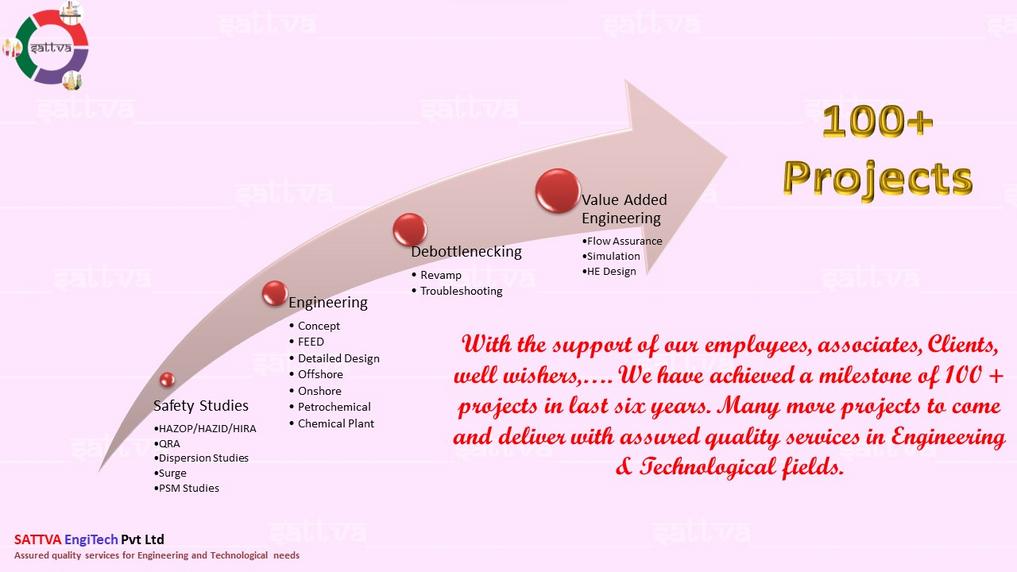

Projects

Conceptual Design Studies/Project

- Integration of flare refinery and Petrochemical France location

Covering Option Study, Calculation verification and proposal finalization.

- FA Study of Sub-sea facility to FPSO having following covering Hydrate, safety concerns (PSV size limitation in downstream system),

- Liquid Recover System of Offshore Compression Facility

Front-End Engineering Design (FEED)

- Two Number Offshore Oil Wellhead platforms Process Engineering (and part of Safety and Mechanical Design)

- FEED Verification of Gas dehydration Unit inclusive of AGRU.

Covering performance all process deliverables verification by performing calculations such as Process Simulation, sizing calculation (Equipment, packages, lines, flare system), Datasheet verification, Process and general reports and its consistency. All the calculations were performed as part of the verification - Single Offshore Oil Wellhead platform Process, Mechanical and part of safety Engineering

Covering performance all Process Design including Design Basis, Process Simulation, PFD, HMB, P&ID, PDS, HAC, HAZID & HAZOP Close-out, Vent Dispersion and radiation Study, F&G Mapping Study, MDS Specialized Items, etc. - Two Offshore Gas Wellhead platform Process, Mechanical, Safety and part of Electrical & instrumentation Engineering-Ongoing

Detailed Design Projects

- Detailed Design of Lube oil Expansion Project, Patalganga, India

- Flare System Design of Nigeria Plant

- Modification in the existing plant for catalyst change

Covering performance all Process Design including Design Basis, Process Simulation,

PFD, HMB, P&ID, Datasheets, inputs to specification, etc.

Extended/Value Engineering

- FA Study of Sub-sea facility to FPSO (North Sea)

- Multi-phase pipeline network (comprising of 43 pipelines) using OLGA for existing field for Flow Assurance activities.

- Online change over Philosophy development of Middle East Client

- Well Test Unit Process Design of Middle East Client

- Preparation of Safeguarding Memorandum and vent system.

- Air SeparationUnit Process Simulation with extensive heat integration and Column Hydraulics

- 5 no. Distillation Column replacement with simulation and Column Hydraulics

- Few Hundred Heat Exchangers Design using HTRI for a petrochemical complex

- Sand Transport modelling in subsea well to FPSO (North Sea)

- FA study of sub-sea well optimization and safeguarding study.

- Flow Assurance Study for well cycling operation covering Crude (Multiphase) Pipeline

- Low -Temperature Flow Assurance Study for processing facility pressurization for black start

- 25 Heat Exchangers Design using EDR

Surge Analysis studies – 6 numbers

- Firewater network of Petrochemical Complex for International Location

- Closed-loop Cooling Water system for International Location

- Community water (180 km distribution) supply at western India rural area

- LNG Receiving Terminal

- Three no. Water pipeline sizing and Surge Analysis of Middle east facility.

- Water Hammer study of water injection network (North Sea)

Process Engineering Consultancy and Safety support

- De-bottleneck Study of existing 11 distillation columns

- Hydraulic study of utilities cooling water, Chilled water, Stream network and hot-oil network

- Energy optimization study inclusive of evaluating overall efficiency of the current system

- Troubleshooting study of the hot oil system

- Engineering Design of de-bottleneck proposals including column, internals, vessels and heat exchangers

Process Safety

- PSM Gap assessment of Process safety for Specialty chemicals plant in Gujarat.

- QRA study for two tank farm units of Krishna Anti-oxidants in the year 2019

- PSM Gap assessment of Process safety for Specialty chemicals plant in Roha, Maharashtra.

- QRA study for two tank farm units of Krishna Anti-oxidants (Ongoing)

- Four no. of Relief Valve Inspection Testing Frequency identification for the different international sites (USA)

HAZOP/HAZID/HIRA Conducted – 15 number

- Continuous Process

- Batch Process

- International Locations

- Online

Training/workshop

- Process Simulation in Mega Engineering, Pune

- Basics of Flow Assurance to Senior Professionals

- PSM Awareness Workshop for Major Pharmaceutical company in Gujarat.